Evolving market dynamics are leading to volatility in supply chains, hampering global operations. Executives are grappling with strategic question – is my supply chain framework aligned for the next to 3 to 5 years of business growth? Do I have the right number and locations for existing distribution centers? Will we be able to improve supply chain efficiency and service levels?

Clients partner with ITC Infotech to address pertinent supply chain challenges through our network design and optimization services – helping businesses strategically plan and design supply chain frameworks and policies to reduce overall all costs and improve service levels.

ITC Infotech’s Digitaligent Supply Chain Design & Optimization

Business Challenges

Businesses with expanding operations require supply chains designed to handle their growth plans. Complex scenarios have to be evaluated and analyzed to arrive at crucial and timely decisions:

- Analyze the product flow and stocking policies in the existing supply chain and identify areas to improve supply chain efficiency

- Improve customer service levels to better serve customers

- Reduce inventory level and stock outs in the supply chain

- Reduce last mile transportation cost and improve utilization of transportation assets

Solution Overview

Network Design & Optimization

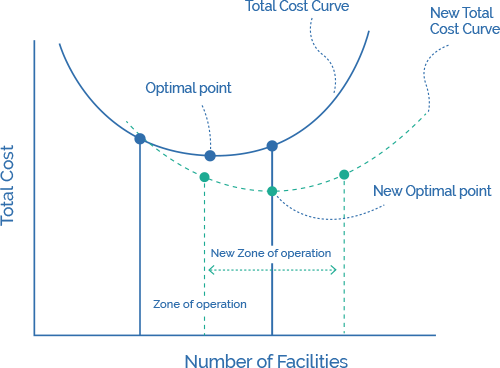

Network Design & Optimization is a decision support system that helps organizations design, build and analyze their supply chain to reduce cost and improve service levels. End-to-end supply chain cost and constraints can be modeled to understand the tradeoff that exists in the supply chain.

Strategic Interventions

Resource acquisition and divestment decision

- Capital investment decision

- Open and close facility decision

- Post merger & acquisition rationalization

- Strategic sourcing decision

- Realignment decision

- Omni Channel Fulfillment

Operational Actions

Improving operational efficiencies

- Flow Path analysis

- Rough cut capacity planning

- Risk analysis and contingency planning

- Cost Vs. Service trade-offs

Tactical Initiatives

Operating policies

- Cost to serve optimization

- Landed cost optimization

- Hub Optimization

- Product mix allocation decision for manufacturing facilities

- Policies decision related to inventory, distribution and sourcing

Inventory Optimization

To reduce inventory stock outs and loss in sales, it is important to define the right inventory norms and policies. Reducing inventory across the supply chain has significant impact on reducing working capital requirements. The right inventory norms can be designed by creating in-depth understanding of customer buying behavior and factors contributing to supply side variability. ITC Infotech’s solution for inventory optimization includes:

Multi-echelon Inventory Optimization

Define inventory level for safety stock, cycle stock and pre-build inventory

Simulation

Validate inventory norms for set service levels

Service-level Optimization

Identify right service levels for SKUs to meet overall objective of service level

Route Optimization

Design routes to reduce transportation cost for last mile, optimize mix and modes of transportation while considering cost and constraints. Our route optimization solution includes:

Periodic Shipment Balancing and Scheduling

Creates routes using daily shipment data to balance and schedule deliveries and pickups across a time period. This enables determining a schedule for multi-stop vehicle routes to minimize costs while adhering to delivery frequency and scheduling requirements.

Continuous Moves Interleaved Shipments

Determines interleaved pick-ups and drop-offs within cohesive routes while considering right-sizing the fleet and mode selection.

Fleet Optimization

Identifies the optimal fleet size and mix of assets based on cost in order to right-size the fleet and determine optimal number and location of assets.

Hub Optimization

Solves hub selection problems by determining right number and locations of hub required for consolidation of shipment in order to reduce overall transportation cost, while meeting service level constraints.

Our comprehensive Supply Chain Design & Optimization services and solutions also cover:

- Consulting: Recommendations on supply chain framework considering long term projections. We also diagnose existing supply chain network to suggest efficiency improvement areas

- Managed Services: Setting up a hybrid development model to build new supply chain models and support existing or new models for regular plan run

- Center of Excellence (CoE): Helping clients build CoE for supply chain design which includes selection of solution platform, establishing processes and setting up teams for delivering results related to supply chain design and optimization

Our extensive experience in offering Supply Chain solutions to companies across industries includes:

- Delivered supply chain design and inventory optimization engagements using Llamasoft Supply Chain solution platform for Manufacturing, Optical lenses, CPG and E-commerce industry

- Designed supply chain for a leading optical manufacturing company, for 2020, which included greenfield analysis to identify locations for distribution centers, define product flow in the supply chain and defining sourcing and distribution policies

- Tactical planning for one of India’s largest CPG company: Our solution included deciding on product mix for a manufacturing plant, pre-build inventory strategy and decision related to distribution lanes and sourcing of raw material and packaging material from suppliers

- Raw Materials (RM) and Finished Goods (FG) Inventory optimization for a leading label and packaging material manufacturing company which involved detailed demand analysis to understand customer buying behavior, identifying and analyzing key supply variability parameters, defining and validating inventory norms and policies using simulation based approach

- Reduced transportation cost by identifying the right number and location of hubs to consolidate LTL shipments, while meeting defined service level constraints

Results

- Overall supply chain cost optimization

- Improvement in customer service level

- Reduction in inventory days of stock

- Reduction of last mile delivery cost and improvement in asset utilization

- Enhanced supply chain decision-making power, with reduced time and effort

- Enhanced risk management and contingency planning