Build

ITC Infotech’s solution from ‘Devices to Decisions’ enables Digital Manufacturing, to improve operational efficiency, flexible & agile operations for a safe & sustainable manufacturing.

Offerings

Smart Factory-as-a-Service helps accelerate the value realization cycle from Industry 4.0 initiatives by leveraging ITC Infotech’s low-intrusion starter pack accelerator designed for manufacturing workloads on a cloud-based subscription model tied to business outcome.

Realtime Operational Visibility

ITC Infotech’s domain led approach for providing business KPI view to shopfloor personas for monitoring of operations and providing process deviation information to take necessary action.

Factory Performance Intelligence

ITC Infotech’s structured approach to provide real-time visibility to manufacturing performance with loss reasons and its root cause, thus providing a line of sight to drive closed-loop continuous improvement in the overall operational efficiency.

Worker productivity – Digital Work Instruction

ITC Infotech makes the transformation to paperless manufacturing easy and seamless by leveraging our deep domain and similar transformational experiences making them accurate and simplifying tasks to the operator, thus improving their efficiency.

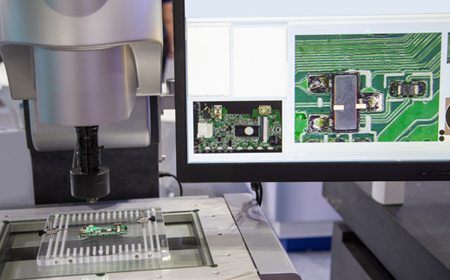

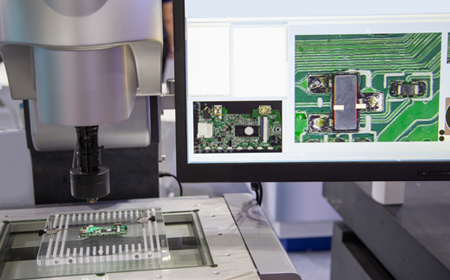

Predictive Quality

Yield optimization using advanced analytics by monitoring various critical process parameters and correlating with historic datasets for predicting possible product quality issues.

Asset Condition Monitoring & Predictive Maintenance

Improve manufacturing asset efficiency, avoid unplanned downtime & reduce maintenance costs with advanced data analytics, machine learning & condition monitoring of assets.

Worker safety

Continuously monitor the health, location, safety, and movement of workers by identifying potential issues and provide insights to decrease risks & safety incidents in work environments.

Sustainability – Energy and Water Management

ITC Infotech helps optimize the consumption of non-renewable resources like water & energy for a sustainable world by providing business-friendly solutions backed with strong analytics to have a 360° view of efficient water utilization, scrap reduction in shop floor & energy optimization.

As factories across the world are learning to adjust to the fluctuations and uncertainties of present times, a robust digital strategy for manufacturing shopfloor will help achieve much-needed cost optimization, productivity, process standardization and efficiency improvement. MES systems play a critical role here by setting the foundation of the factory’s digital transformation journey.

Solution Design

Global template design & development, visualization dashboards, charts & reports, product configuration, automated testing

Upgrade and Rollout

Industrialized deployment (across GEOs), organization change management, upgrades, site-specific upgrades & solutions

Integration

Integration with L4 systems (ERP, PLM, etc.), integration with L2 systems (machines, OPC, etc.), standards-based integration, custom integration

Maintenance and support

SLA-based 24X7 support, environment monitoring and management, multi-level support (L1 to L3) under a single platform

ITC Infotech’s offering for product design and product lifecycle management coupled with strong digital manufacturing capabilities helps in delivering a comprehensive digital thread solution to the market.

Connected Asset-as-a-Service

ITC Infotech helps OEM manufacturers align processes, people, and technology to deliver products in a pay-as-you-go model, thus reducing the CAPEX and enhancing customer experience.

Digital Thread

Enable a closed-loop value chain of as designed vs as manufactured vs as operated leveraging analytics, simulation, and augmented visualization capabilities.

Provide machine and equipment connectivity in a brown field environment for acquisition of process data from existing PLC and SCADA systems and newly installed sensor data for enabling digital manufacturing use cases.

The offering comprises of

- Standardized templates to identify plant connectivity needs and right-fit solutions

- Catalog of sensors, gateways, and connectivity options

- Rollout toolkit for standardizing engineering activities

Secure OT network and Edge devices for seamless IT-OT convergence. ITC Infotech’s solution provides round the clock protection against any threat and security issues, thus ensuring a secure movement of manufacturing workloads & data to cloud.

Deep supply chain domain knowledge from working with parent organization for a more agile, flexible & intuitive supply chain that is tightly integrated with seamless dataflow between demand, capacity & supply chain planning.

Supply Chain Control Tower

ITC Infotech provides a detailed and granular recommendation on inventory, production & distribution management within the execution window to ensure demand & supply balance despite variations and disturbances in the supply chain.

Predictive Demand Forecasting

With the right combination of advanced analytics capabilities and understanding of the supply chain domain, insights are derived for challenging supply chain problems.

Logistics Management

Efficiently manage logistics with increasing demand for online deliveries, requirement for shorter delivery cycles, growing competition, shrinking margins, and ensuring better customer service.

ITC Infotech reimagines plants and facilities with the latest digital technologies and Industry 4.0 solutions to transform people experience, create a collaborative culture, become more sustainable by conserving resources, and achieve higher operational efficiencies.

Smart Facilities

IoT solutions for energy efficiency, water conservation and efficient waste management, scrap reduction and efficiency gains on the shop floor are also prioritized.

Smart Surveillance

Smart surveillance command center brings in multiple use cases for employee counting, unidentified object detection, worker safety monitoring, and security breach detection.

Industry 4.0 requires tighter integration with shop floor automation systems and the rest of the enterprise. ITC Infotech navigates clients through the IT-OT integration journey to enable manufacturers realize the benefits of connected shopfloor.