Persistent challenges in maintaining market share and leadership have prompted Consumer Goods companies to opt for unique network configurations to optimize their supply chain – one that offers lowest total cost of ownership, provides sourcing information, delivers intelligent analysis and maximizes profits by taking into consideration financial and operational risks.

Consumer goods majors leverage ITC Infotech’s Smart Network Design to execute operational sustainability, bring in cost-effectiveness and create business alignment. ITC Infotech applies digitaligence to strategic network design, improving their client’s financial performance through increased revenues, reduced costs and enhanced flexibility to respond to market dynamics.

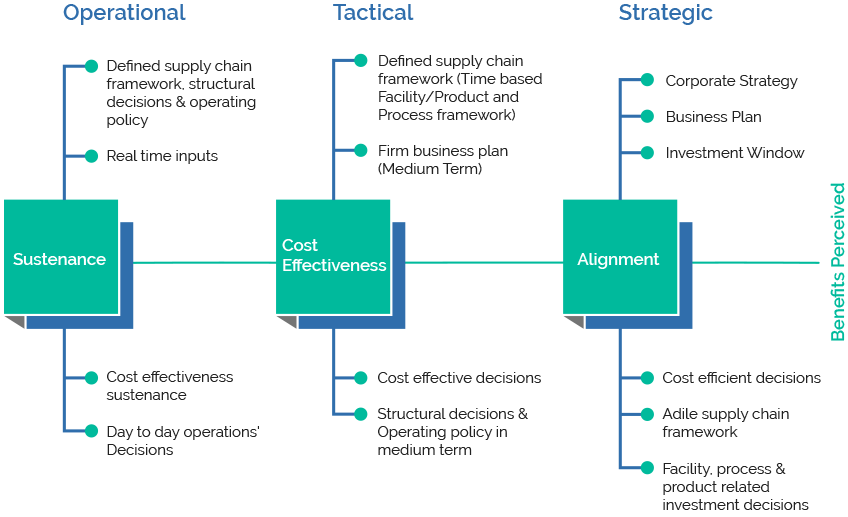

Strategic Network Design Framework

Business Challenges

CPG businesses need to balance supply and demand carefully, in order to be able to better deal with issues like stock-out and lost sales.

- Frequent introduction of new products

- High inventory across supply chain leading to low responsiveness

- Bottlenecks leading to reduced fill rate, even with manufacturing efficiencies in place

- High obsolescence levels for procured materials

- OOS for top-selling and stock aging for low-selling SKUs

- High growth leading to capacity constraints

- Macroeconomic factors like GST

Solution Overview

ITC Infotech’s S&OP process framework helps clients strike a scientific balance between demand and supply, while keeping budgets on track.

Resource Acquisition and Divestment

- Decisions on facility opening and closing

- Product portfolio related decisions

- Capacity augmentation vs outsourcing decision

- High-level trade-off decisions

- Automation uptake and forgo

Structural Decisions

- Defining roles of various facilities

- Market planning

- Product promotion planning

- Transportation mode selection

- Network structure

Operating Policies

- Prebuild strategy

- Inventory versus service trade-off

- Warehouse booking plan

- Capacity realignment

- Postponement strategy

- Production SKU mix decision

- Raw Materials and Finished Goods (RM &FG) sourcing network

Operational Efficiency

- Rough-cut-capacity-planning (RCCP) and firm distribution network

- Shipment sizing and scheduling

- Load optimization

- Route planning

- Contract labor optimization

- Safety stock and cycle stock optimization

- Simulation and low level sensitivity analysis

ITC Infotech has developed a unique ‘SAVE’ methodology to ensure every client’s success:

- Sourcing Information: Understanding the client’s unique business requirements and strategy, gaining competitive and value chain framework insights, mapping existent operation strategy and identifying key stakeholder to map readiness for change

- Analysis: Classifying KPIs, benchmarking success factors, checking effect of distribution network redesign on other business processes, developing high-level model framework, time estimation and critical data collation

- Validation: Building baselines and optimized models, performing cross alternative sensitivity analysis to arrive at final scenario, creating business process impact metrics, implementation road map, final KPIs and redesign process flows

- Execution: Execute changes as per road map, run simulations to generate performance metrics, implement user training, and run awareness programs followed by monitoring adoption and success factors continuously to ascertain solution effectiveness

Results

A strategic network design can help improve overall supply chain process.

Since supply chains consists of multiple functions within an organization, its success heavily depends on the level of collaboration across departments. Function-wise optimization gives suboptimal results as compared to end-to-end optimization exercises.

Clients leverage our expertise to help them periodically asses and align their supply chain networks with the changing dynamics.

- Improved supply chain reliability

- Improved supply chain responsiveness

- Minimized landed cost at warehouse